Industrial Manufacturing & Custom Fabrication

Obsidian 3D offers precision 3D data capture for design, production, and inspection workflows, ensuring accuracy and enabling efficient product lifecycle management. Our services provide highly accurate dimensional data and digital twins of physical objects or environments, serving as a bridge between design intent and fabrication reality.

This technology empowers fabricators to enhance precision, accelerate production, and ensure perfect fit-up, directly impacting your bottom line.

-

Create highly accurate 3D digital models from existing physical parts, assemblies, or field conditions, ensuring new components or fabrications integrate perfectly. When fabricating a custom steel frame to fit around existing machinery where no CAD data exists, 3D scanning the environment captures exact dimensions and obstructions in minutes to hours. This replaces traditional manual measurement methods that could take days and still result in errors, preventing costly re-fabrication due to misfits and saving thousands to tens of thousands of dollars per complex custom job.

-

Accurately inspect and verify the dimensions of custom tooling, jigs, and fixtures, ensuring they precisely hold parts for fabrication or machining processes. Scanning a newly fabricated welding jig against its CAD model can identify deviations in minutes. Catching even small errors at this stage prevents the production of hundreds or thousands of non-conforming parts, saving significant material and labor costs that would arise from downstream quality issues.

-

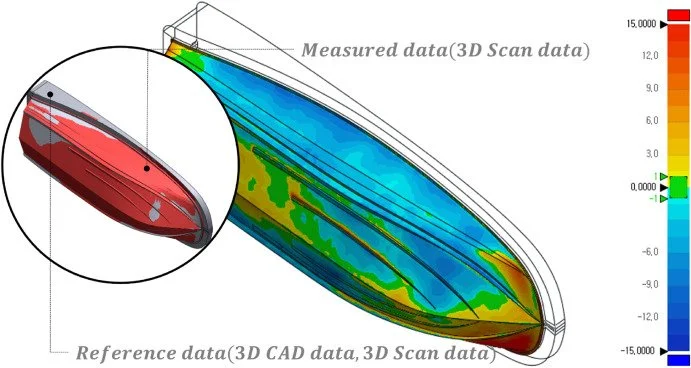

Perform non-contact, high-accuracy dimensional inspection of fabricated components by comparing scanned parts to their CAD models, ensuring they meet specifications before assembly. For large-scale aluminum weldments or complex CNC-machined parts, scanning allows for rapid comparison to design specifications. Identifying a critical dimensional error before shipping or final assembly can prevent costly field rework, logistical nightmares, and customer dissatisfaction, potentially saving tens of thousands of dollars in rework and expedited shipping.

-

Leverage precise scan data for custom parts and complex assemblies, optimizing sheet metal design, mechanical design, and detailing for fabrication. When fabricating bespoke architectural elements or intricate metalwork, 3D scanning ensures that each component fits precisely into its unique spatial context. This can reduce on-site installation time for complex fabricated structures by 20-30% due to fewer adjustments and clearer understanding, saving valuable labor hours and preventing schedule overruns.

How We Deliver Cost & Time Savings for Manufacturing & Fabrication

Real-World Applications

Advanced Reverse Engineering:

Create highly precise 3D digital models of existing physical parts, products, or tooling for which no CAD data exists, ensuring manufacturability.

Comprehensive Quality Control & Inspection:

Perform non-contact, high-accuracy dimensional inspection by comparing scanned parts to their CAD models.

Optimized Tooling & Fixture Design/Verification:

Accurately inspect and then design/modify molds, dies, jigs, and fixtures.

Accelerated Product Development & Prototyping:

Rapidly capture and digitize physical prototypes, enabling faster iteration and concept validation.

Digital Archiving & Replication:

Create precise digital libraries of parts and products for future reference, modification, or re-manufacturing.

Custom Fabrication:

Leverage scan data for custom parts, including sheet metal design and mechanical detailing.